warehouse management process

An optimized receiving process can also affect how you store manage and track your products. The warehouse receiving process steps include delivery of the products unloading from the delivery trunk and inventory storage.

|

| Pin By Facts Computer Software L L C On Software For Inventory Warehouse Management Warehouse Management Process Flow Chart |

In this step the transferring of ownership of goods is involved especially financial responsibility.

. Check in with your workers. By keeping the warehouse clean and organized youll help your employees find items faster. Our platform wraps around your processes instead of forcing you to stuff them into. The goal of warehousing management is to develop effective.

Warehouse management is defined as the process of managing the operations within a warehouse. When you first start warehouse management make sure to establish clear guidelines for your employees on how items should be stored and where theyre all located. The next step is creating and finalizing a warehouse management process flow. Step 4 Picking.

Its a subcomponent of warehouse organization. A process flow can be created through a few methods. A warehouse management process is the defined way in which an organizations warehouse operates. It boosts customer compliance in terms of labeling documentation shipping and data flow.

Bugs in configuration are also addressed by the WMS provider implementation team. A process flow illustrates how goods are received the process they go through how they are shipped and any stages in between. Warehouse inventory management and control. Having a warehouse management system enables information sharing across the enterprise retail locations and to every stakeholder.

This will speed the warehouse pick. Then a picking list guide is produced to help the pickers in their activities. Lets look at various types of process flow charts and how you can use them in your warehouse. The WMS will pull this data and streamline how warehouse staff source inventory like displaying the location of a single SKU within a 10000 square foot warehouse.

This can mean many things depending on the needs of your unique business. What are the steps in Warehouse Management System Process. Use the inventory software to track data and forecast demand. A warehouse management system WMS is software that streamlines every part of warehouse management from receiving and storage to picking packing shipping inventory tracking and all the steps in between.

Tools and techniques used to monitor and optimize them. This includes purchases or services delivered within a set time for the customer. The Warehouse management module lets you manage warehouse processes in manufacturing distribution and retail companies. This sounds simple but there are many aspects to the internal operations including a wide variety of processes that occur.

Testing is usually performed using real warehouse data comparing the results of warehouse process execution in both systems. Picking and packing are two core functions performed in a warehouse. The six fundamental warehouse processes comprise receiving putaway storage picking packing and shipping. This is the ideal solution because.

A WMS helps companies increase operational efficiency and reduce waste and costs while improving labor management and customer and. Below we will go through each step of the ISO warehouse management process and how to optimize these steps to help you manage your inventory effectively. A warehouse management system process flow is a visual chart or diagram that shows the main activities of your warehouse. An IMS is a subsection of the warehouse management process hence why it should be integrated with your WMS.

The last decade has seen e-commerce and other online marketplaces explode in popularity. As mentioned above the warehouse management process will include 7 steps from warehousing warehousing to picking packing returning checking and reporting. Warehouse management is the process of administering and controlling the operations within the warehouse and synchronizing it with the entire supply chain. Keep reading to learn more about how you can better manage and improve the operational procedures of your warehouse.

Best practices but are stuck trying to implement them in your system consider SkuNexus. Warehouse Management Process Flow. Picking is the act of collecting stock in order to fulfill a customers order. A warehouse management system should generate pick lists for each picker to retrieve items in the most efficient way.

This trend has led to the development of warehouse inventory management processes that help manufacturers wholesalers distributors and retailers meet the needs of customers looking to buy products directly from wholesalers or retailers rather than manufacturers. Mar 24 2021 11 MIN READ. This may include zone picking wave picking or batch picking. Softeon is one of the best warehouse management systems that optimize distribution inventory management receiving putaway order picking loading and shipping.

Move items from the receiving dock to their correct storage locations. Check in and log incoming items. Lean warehouse management methods are taking a center stage in the current times due to apparent business advantages as they yield more profit with fewer investments. A warehouse management system process flow is.

Intaking identifying inspecting and storing inventory. When a customer order is received a checking process should be performed to verify that the products are available for the customer. The warehouse receiving process is one of the most important steps of supply chain management for eCommerce sites. This module has a wide range of features to support the warehouse facility at an optimal level at any time.

The warehouse pick process is all about consistency. These activities are normally accomplished by a warehouse management system WMS. Verify that youre receiving the right quantity in the right condition. Warehousing is an easily overlooked step in the warehouse management process but it is a step that helps increase the efficiency of warehouse management.

More than what goes on day-to-day or month-over-month a warehouse management process defines documents and enforces. This is the most expensive step in the warehouse management process accounting for about 55 of. It is a process of creating an invoice to get the selling price from the customer. Optimizing these six processes will allow you to streamline your warehouse operation reduce cost errors and achieve a higher perfect order rate.

This makes inventory accuracy and tracking all the more important. Disjointed teams and employees. A well-thought-out warehouse management process flow reduces time and money on the daily. Processes such as picking packaging marking weighing and delivering products from the warehouse to the customer.

Different warehousing scenarios are tested and bugs in the design are fixed by the warehouse management system supplier. Team members involved in these processes. Warehouse Management Processes Receiving. It starts as the inventory enters the storage facility and it ends until the product becomes sold consumed outdated or transferred to some other facility.

Warehouse management is fully integrated with other business processes such as transportation manufacturing. Poorly-managed warehouses run into a host of problems all of which impact profitability. 5 Softeon Best for end-to-end Supply chain Processes. Invest in a competent and experienced warehouse manager.

Warehouse management is the process of controlling and optimizing product storage and other various operations in the warehouse. Invest in technologies that support the growth of your business.

|

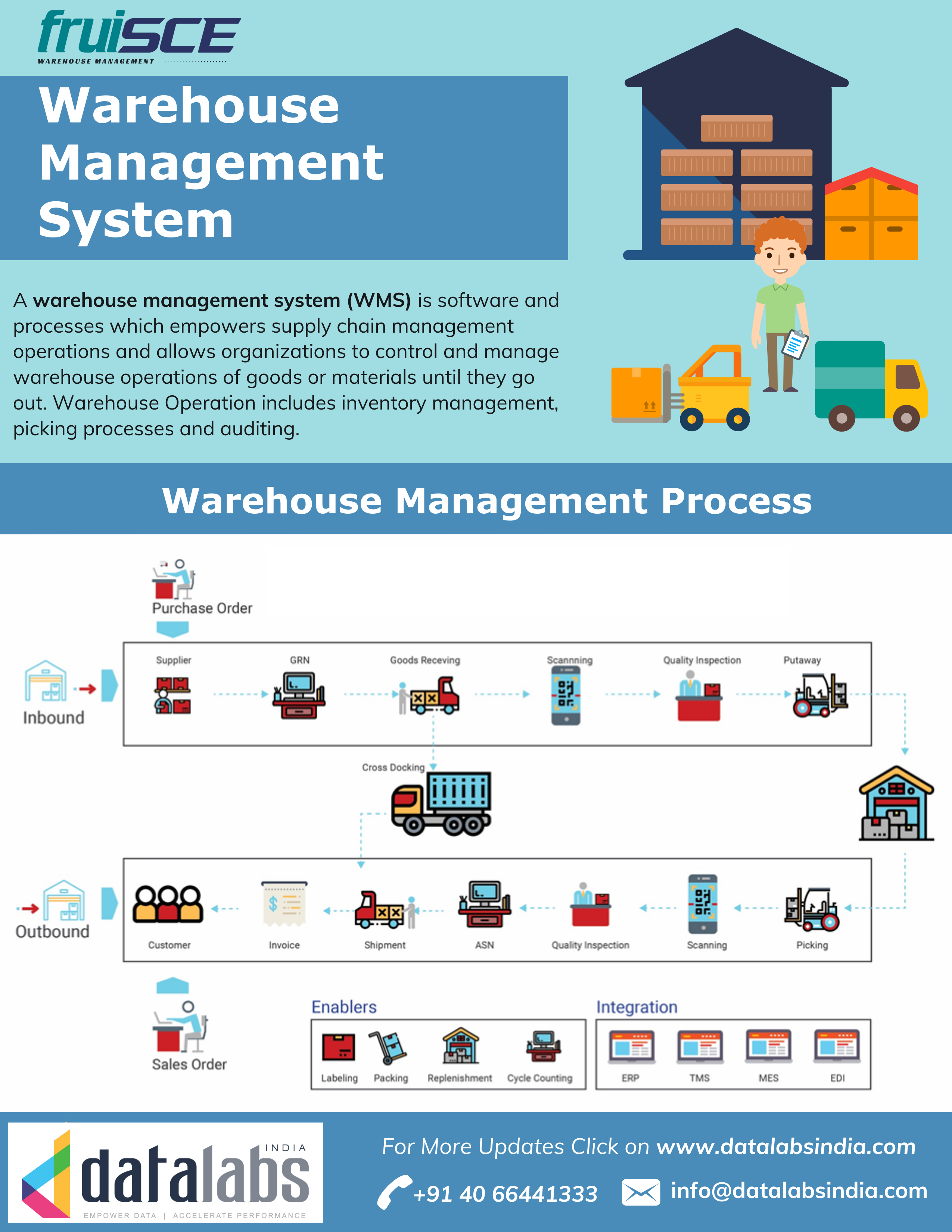

| What Is The Complete Process Of Warehouse Management System Warehouse Management Warehouse Management System Supply Chain Management |

|

| Inventory Management Flowchart Flow Chart Business Process Management Warehouse Management |

|

| Warehouse Management System Warehouse Management Warehouse Management System Logistics Management |

|

| Inventory Management Workflow Inventory Management Management Business Process Management |

|

| Inventory Chart Warehouse Management Flow Chart Management |

Posting Komentar untuk "warehouse management process"